Maren Jewelery and the Kauselmann jewelry foundry We have a long-standing partnership based on trust, quality and a shared passion for exceptional jewelry. For us, the focus is not only on the end product, but also on the values and principles that stand behind every creation. The Kauselmann foundry is an important part of our production; it transforms our 3D visions into beautiful, tangible pieces of jewelry..

Meet the Maker: Jewelry Foundry Kauselmann

A look behind the scenes of our jewelry production

Our Teamwork

The jewelry foundry Kauselmann was founded on July 1, 1990, by Mr. Bernhard Kauselmann, who had previously gained over 20 years of professional experience. At that time, the company started with a staff of three people. Today, the foundry employs 130 staff members and is located in Pforzheim, a city known for its history in jewelry manufacturing.

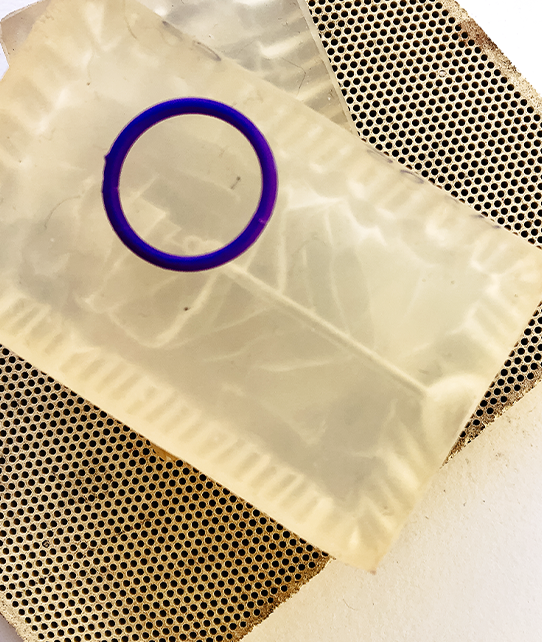

cast tree with wax models

The craft of jewelry casting

The craftsmanship behind our jewelry is a work of art in itself. Each of our designs goes through a complex process in which the Kauselmann jewelry foundry plays a crucial role. They have mastered the art of casting to perfection, from the traditional wax melting process to the modern use of CAD and 3D printing. The details and intricacies of our jewelry come to life with remarkable dedication and precision. The casting process begins with the traditional wax melting process and has evolved from earlier jewelry centrifugal casting to advanced vacuum casting, a technique in which wax parts are produced by wax injection after mold creation. Today, CAD and 3D printing are becoming increasingly important to create castable waxes that form the basis for our unique jewelry pieces.

3D printing (left) and wax model with silicone mold (right)

Vacuum Casting

Vacuum casting for jewelry is a specialized casting process that enables precise, high-quality production of jewelry and parts. The process begins with the creation of a wax model, which is produced using CAD designs and 3D printers. This wax model serves as a template for the casting. The wax model is then mounted on a cast tree and embedded with a plaster-like mass. This mold with the investment material is heated, whereby the wax inside melts and leaves a cavity in the investment material. The liquid metal is then poured in here..

The actual casting process takes place under vacuum conditions, which avoids air bubbles or other impurities in the casting material. The heat melts the metal, which then flows into the mold's molten cavities to fill the shape of the jewelry piece. Once the metal has hardened, the investment material from the mold is removed and the piece of jewelry is cleaned, polished in the Maren Studio and subjected to further processing steps to obtain its final shape and surface finish. Due to its precise and clean process, vacuum casting offers an excellent opportunity to produce high-quality and detailed jewelry castings.

Sustainability in focus

Our long-standing partnership with the Kauselmann jewelry foundry is based on shared values of sustainability and ethics. Their abandonment of mined gold in favor of COC materials and reprocessing fits perfectly with our sustainable standards. Since the beginning of 2020, the Kauselmann foundry has no longer used mined gold in its gold standard alloys, which has led to a drastic improvement in the carbon footprint of its cast products. This decision takes into account ecological and ethical reasons, which fits perfectly with our goal of producing high-quality jewelry in a sustainable way.

In addition, Kauselmann is committed to sustainability in its Code of Conduct

Production methods. They continually invest in energy efficiency, disposal, health and employee satisfaction. Your measures include exhaust air and extraction systems, water circulation, solar energy generation and the optimization of work processes. They use paper bags instead of plastic packaging for shipping to customers and rely on a water recovery cycle and large-scale solar energy. These efforts underscore our joint efforts towards environmentally conscious production of high-quality jewelry.

Shared passion for first-class jewelry

A big thank you goes to the Kauselmann jewelry foundry. Their expertise and dedication transform our 3D designs into unique jewelry castings that embody craftsmanship and individual beauty. Collaborating with them is invaluable in our commitment to creating outstanding jewelry that is not only aesthetically pleasing but also embodies our values and responsibilities.

We hope that this insight into our partnership has further deepened your enthusiasm for our jewelry. At Maren Jewellery, it's not just the designs that are in the spotlight, but also the people and values behind them. Thank you for being part of our journey and sharing our passion for unique jewelry.

Written By Helge Maren