The jewelry craftsmanship is our great passion. That’s why it is particularly important to us that all our partners are just as passionate about the raw materials and sustainability as we are. Because: The piece of jewelry we design can only be as good as the materials we use as a foundation – and thus as good as our partners.

Working Together

From hand to craft

Responsible Jewelery Council (RJC)

But: It is particularly important to us that our partners not only deliver excellent results, but that the path to achieving them – the working conditions, fair wages, and a responsible approach to nature – aligns with our values. Therefore, we are pleased that three of our partners, whom we are introducing to you today, are RJC certified, just as we at Maren are certified. This is a voluntary assessment of environmental friendliness, working conditions, human rights, and mining – all to ensure that the jewelry we produce together is truly beautiful.

18k recycled gold

Our sustainable jewelry consists mostly of gold. You can read about gold and why we chose recycled gold in our Journal on Urban Mining read. And we are incredibly happy that we are with C. Hafner having a partner who cares about sustainable gold just as much as we do: The gold from C. Hafner is through a special technology not only CO2 neutral, but also 100 percent recycled. Just like us at Maren Jewellery, our Pforzheim partner primarily sees himself as responsible for setting new standards and standing up for what he believes in: the protection of nature, fair working conditions, and beautiful gold that no longer harms the earth. Thanks to the remarkable, RJC-certified work of C. Hafner, we can also say: Gold cannot get any more beautiful.

Synthetic Eco Diamonds

The raw material that we use most frequently, after gold, is our diamonds. Instead of buying newly created diamonds, about which we often cannot say for sure where they come from, or whether nature and people are harmed in the procurement process, we have opted for lab-grown diamonds. If you want to learn more about this, feel free to check out our journal on synthetic diamonds.

ear studs

With the gold from C. Hafner and the synthetic Eco diamonds that we receive from Swiss Diamond Vision, Fenix Diamonds and Diamond Foundry Many of our jewelry pieces can already be made to order – our pendants and rings. Because: We focus not only on clarity in design but also in the selection of our raw materials. But what about Ohrsteckern? Here we had to search for a long time to find a partner who produces the so-called earring backs in the Maren Jewellery way: sustainably, fairly, and responsibly. Because most earring backs are manufactured in Asian countries, without being able to ensure who exactly produces them and under what conditions. With Hoover & Strong We have found a partner who leaves no questions unanswered. Everything they produce is made with 100 percent recycled precious metals under the best, responsible conditions in America – and all of it is RJC certified. So now we have the raw materials for pendants, rings, and earrings. But what about chains?

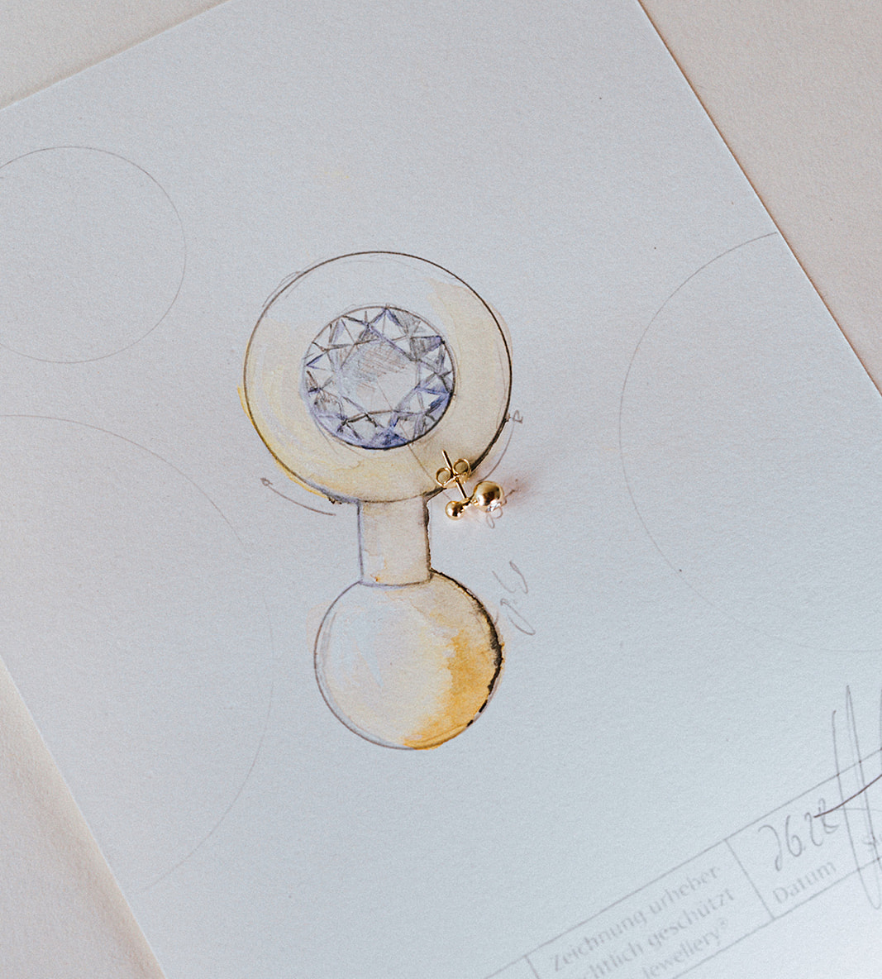

Designing jewelry can be a puzzle

Our essential chain

That's where Schofer comes into play. A production facility in Pforzheim for wonderfully delicate chains. Schofer produces the reduced Essential Chain for us from 18-carat recycled gold. This is an incredibly filigree chain – and we are more than happy to have found a partner who brings the professional knowledge and expertise to produce it exactly as we envisioned. We are also very pleased that Schofer is RJC certified.

Maren Production Chain

Our silver chains

Because we wanted to offer our silver chains made from recycled 925 sterling silver, there was only one choice for us: FischerA company from Idar-Oberstein, whose values are as reliable as the materials they process – and have been for over 70 years. But above all: They are just as demanding as we are. A craft business that takes the production of our chains as seriously as if they had designed them themselves. Designing jewelry can sometimes feel like a puzzle. We know what materials we need to create a piece of jewelry. But where are we supposed to find them? Sometimes you get unlucky and they simply don't exist. For example: Sustainable chain clasps. But for exactly such cases, we have our workbench. That's why we sat down and designed them ourselves. With that, we have the raw materials for: rings, pendants, and earrings. For chains, we already have everything. But: Raw materials are not jewelry pieces. That's why we still need a foundry to shape our gold, our silver into the right form.

Our foundry

Kauselmann is a foundry that completely avoids mining gold and produces in Pforzheim. And their principles are clear: no inhumane working conditions, no environmental pollution, no child labor in gold extraction. That is why the foundry has also decided to use paper bags instead of the usual plastic bags for shipping their casts. This saves them several million plastic bags! Where they do not compromise: jewelry of the highest quality, precisely according to our specifications. But the pure cast is not yet a finished piece of jewelry. Now it needs to be polished.

Our master jewel setter

We briefly summarize: Our gold and silver has been cast and polished. Earring backs have been attached to the studs. Our chains have been crafted. And we have synthetic eco diamonds. But how do the diamonds become part of the jewelry? For that, there is gemstone setter master Wilhelm Kling and his daughter Julia Kling. A traditional company from Pforzheim that has been practicing its craft since 1875. That's 145 years of experience. Experience that convinces many renowned customers. Every hand movement is precise, as every Maren Jewellery customer can attest.

The last glance

Now they all lie before us on the workbench: The chains and rings, bracelets and earrings. And we wouldn't be Maren Jewellery if we didn't get involved ourselves one more time. After all, it's what we love, what excites and fascinates us: The search for the perfect piece of jewelry. We take care of the final polishing and quality control, and of course, we work in an environmentally friendly way – without toxic chemicals, which is why we use citric acid instead of toxic acids for our pickling. Therefore, you can be sure: Each of our sustainable jewelry pieces goes through many conscientious hands, is examined by many knowledgeable eyes, and receives exactly what it needs to be one: Your new favorite piece.

From this blog post

Written By Moritz Hackl